MAINTENANCE MACHINES

Efficient and precise maintenance is essential to ensuring the safety, reliability, and longevity of railway vehicles. Maintenance machines play a critical role in optimizing operational efficiency, minimizing downtime, and extending the service life of key components such as wheels, bogies, and suspension systems. The range of specialized maintenance machines includes sand filling systems, wheel presses, bogie presses, dummy bogies, and trolleys, each designed to streamline servicing processes while maintaining industry standards. By integrating maintenance machines, railway operators can reduce manual labor, enhance precision, and improve turnaround times for essential servicing tasks. These technologies contribute to safer, more efficient, and cost-effective railway operations, ensuring that rolling stock remains in peak condition throughout its lifecycle.

The railway vehicle consumes the sand for eliminating weak friction between the wheel and rail while it's running on the rail. Daily or weekly this lost sand must be refilled.

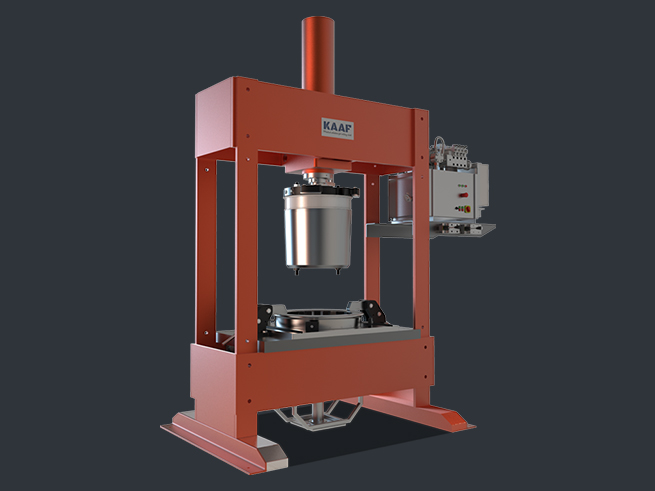

Specially designed machines are used for the assembly and disassembly of the Bochum 54 pre-tensioned resilient wheel used in rolling stock.

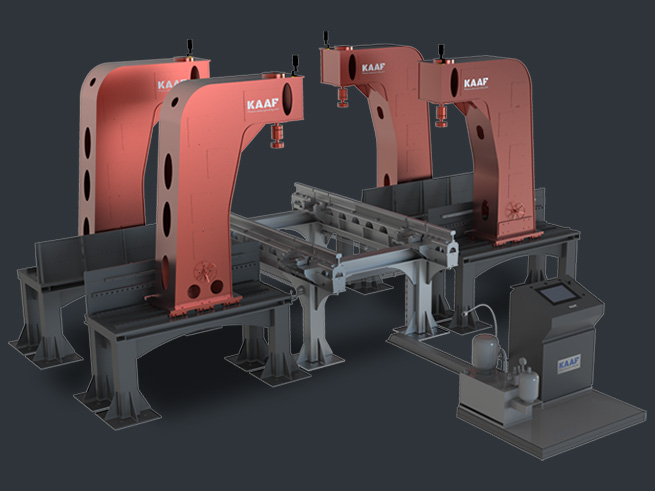

Bogies have a great impact on the safety, comfort, maintenance cost, and similar parameters of rail system vehicles.

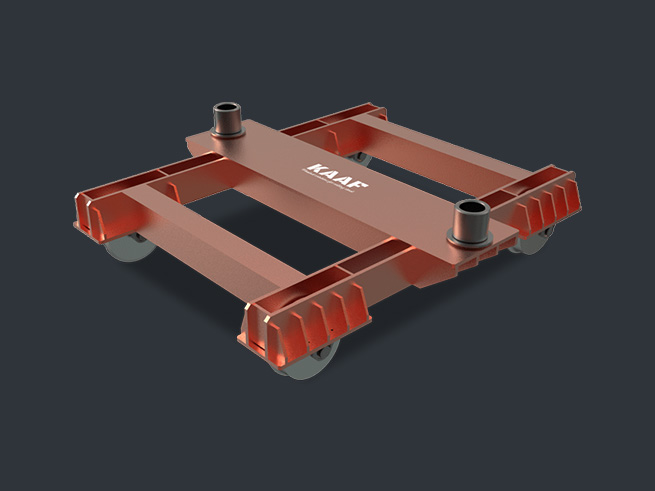

It replaces the principal bogie when it is not mounted on the vehicle body in rolling stock manufacturing factories or the...

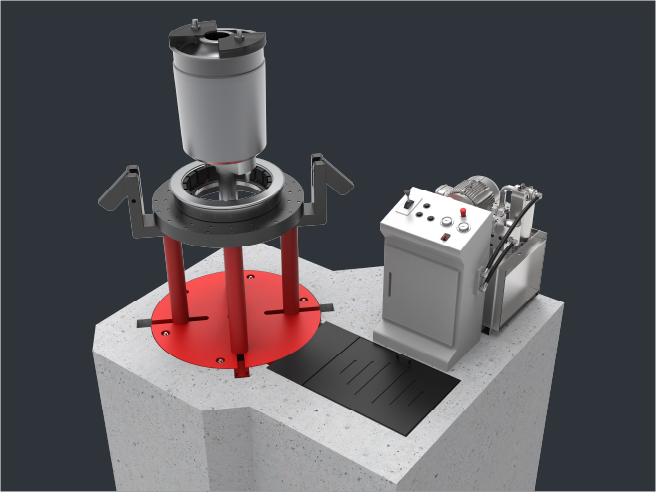

Under-Floor Wheel Press ensures precise assembly of pre-compressed rubbers to wheels. Customizable for types of wheels, ...