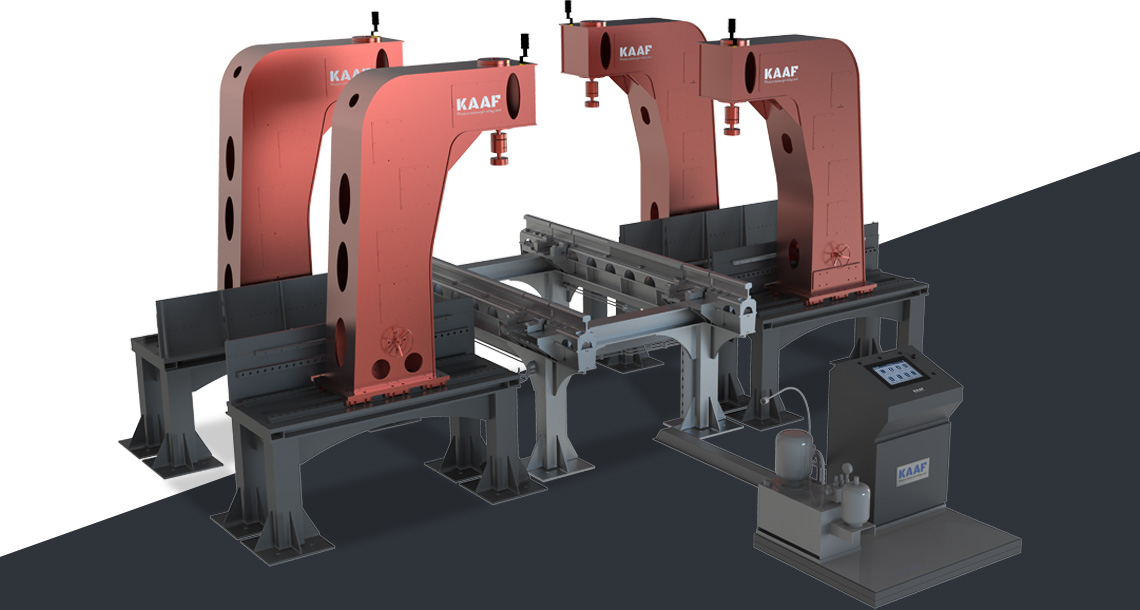

Bogie Test Press

Designed to validate and optimize the performance of railway bogies, this high-precision test system ensures accurate adjustments before installation, guarantees even weight distribution across all wheels, and simulates real-world operating conditions to enhance safety and reliability.

Key Functions:

Accurate Adjustment – Enables precise ride height adjustments for optimal bogie performance.

Weight Distribution – Ensures balanced weight allocation across all wheels, enhancing stability and efficiency.

Realistic Simulation – Replicates real-drive weight conditions to validate operational reliability.

Comprehensive Measurement Capabilities:

Axle Distance & Parallelism – Ensures correct alignment and spacing.

Wheel Diameter & Shoulder Distance – Verifies wheel dimensions for proper contact and load distribution.

Axle Angle & Suspension TOR – Optimizes bogie geometry for smooth operation.

Flexible Installation & Customization:

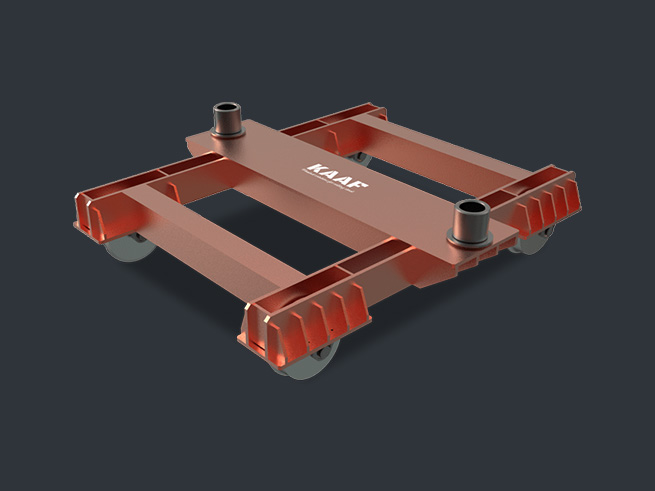

Above-Ground or Underground Configurations – Adaptable to different workshop layouts.

Closed-Frame or Floor-Mounted Options – Customizable to meet specific operational needs.

Modular Design – Allows modifications based on testing requirements.

Bogie Test Press is engineered to enhance efficiency, reduce maintenance costs, and ensure long-term durability. Designed with flexibility and precision in mind, it is an essential solution for railway operators and maintenance facilities seeking superior bogie performance.

With this balancing to be made with the bogie press, the rolling stock will have the following gains:

- De-rail safety even at high speeds

- De-rail safety at high axle loads and low speeds

- High driving comfort

- Low noise level

- Reduction in the number of malfunctions

- Reduction in downtime due to malfunction

- Reduction in operating cost

Bogie press meeting the requirements of DIN25043-7 is manufactured by adapting to customer needs. Bogie press key features:

- Computer-controlled independent hydraulic arms

- Touch screen that allows the user to track the test process flow instantly.

- Torque arms equipped with precision proportional directional control valves

- Compact structural design that facilitates access to measurement and control points on the bogie

- Load cells that precisely measure the loads on the wheels and the forces applied to the suspensions

- Hydraulics power unit equipped with temperature, level, filter, and similar sensors.

- Hydraulic accumulator minimizing energy consumption

Optional specifications that can be added to the bogie press:

- Distance measurement between axles

- Back-to-back measurement between wheels

- Parallelism measurement between axles

- Measurements of the heights from the rail top elevation of the secondary suspensions

- Wheel diameter measurement

- Axle angle measurement

- Other optional features