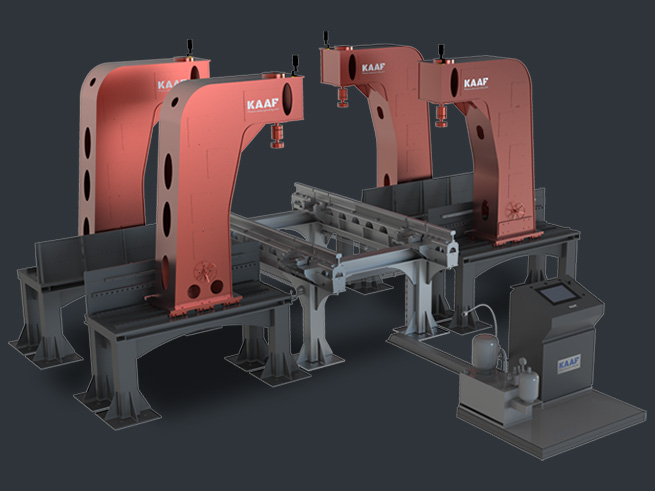

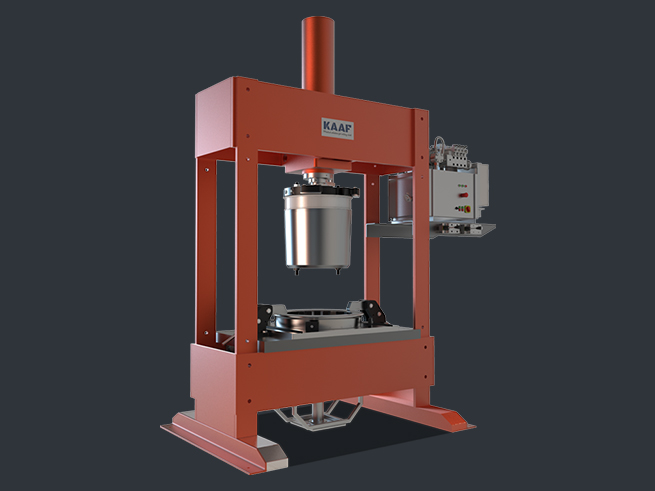

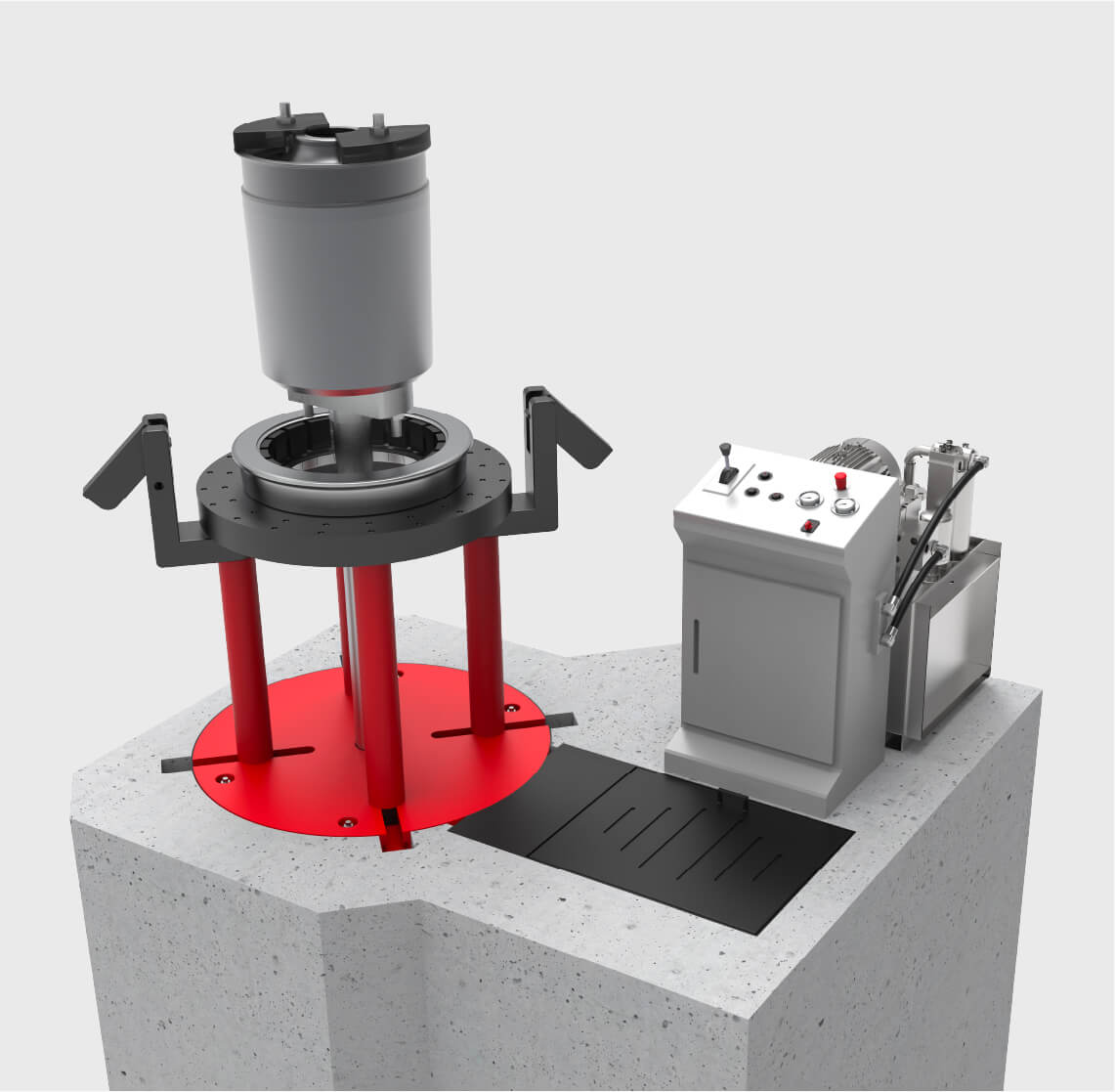

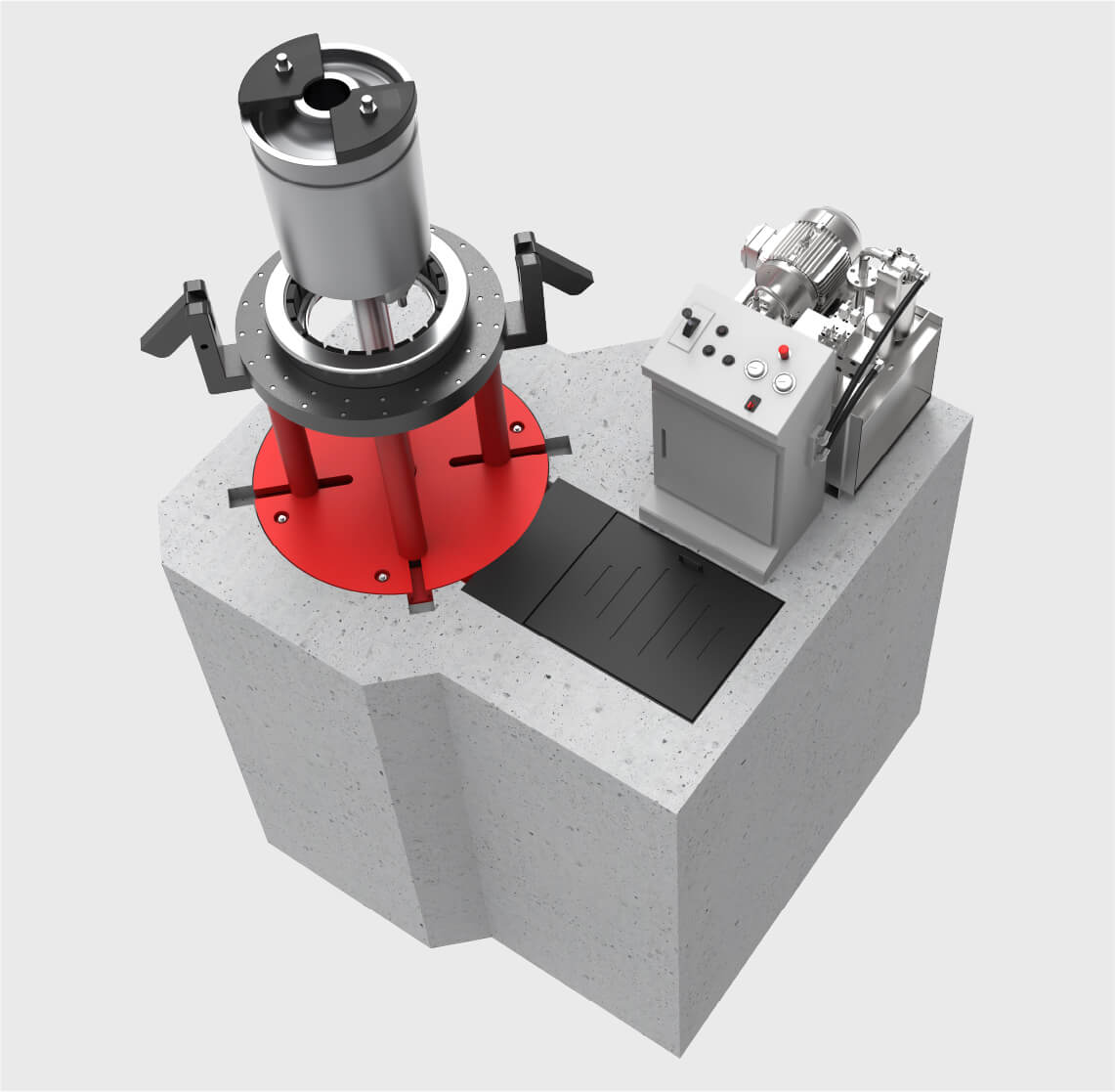

Under-Floor Resilient Wheel Press

Pre-compressed rubbers can be mounted to resilient wheels only with specially designed machines used to assemble rubbers between the wheel center and tyre. KAAF Resilient Wheel Presses enable assembly by applying the necessary pre-compressed force required for the Bo'54 wheel at a precise position, force, and speed. The machines can be customized according to customer demands and different types of wheels. Production is carried out with a force application capacity of up to 500 tons. Additionally, the molds and equipment required for mounting the wheels are designed and supplied with the machine.

Key Advantages of Under-Floor Wheel Press:

Product Features

| PRODUCT FEATURES | DETAIL |

|---|---|

| Model | K10438 |

| Machine Type | Under Floor |

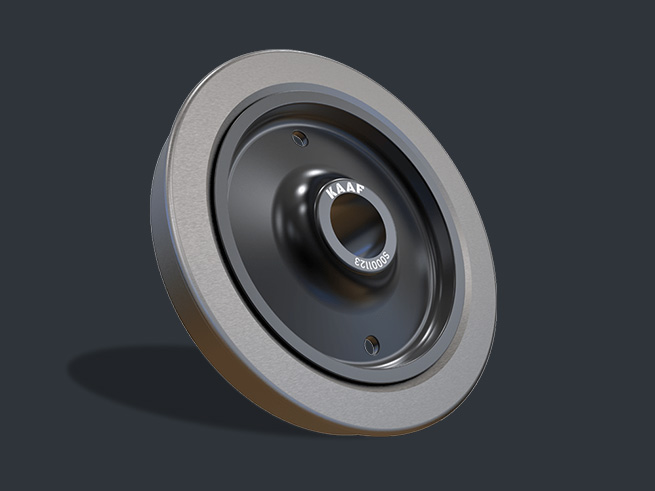

| Mounting Method | Pre-tensioned Mounting with Compression Cone |

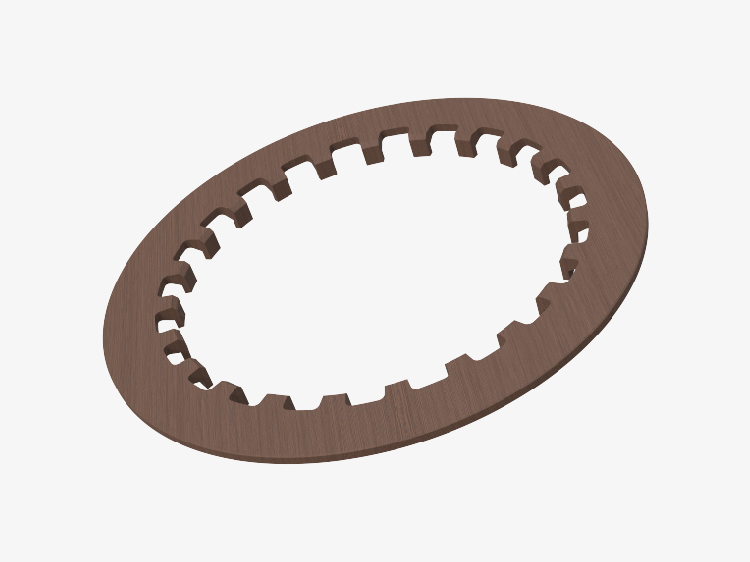

| Compatible Type of Resilient Wheels | Bochum’54 |

| Compatible Diameter Range of Resilient Wheels | Oriented acc. to customer wheel diameter |

| Machine Dimension | ~1200(h)x2200x1200mm |

| Machine Floor Depth Dimensions | ~2000(h)x2200x1700mm |

| Number of Pistons | Single Piston |

| Power of The Machine | 17 KW |

| Operation Voltage | 380V AC (three-phase) / 50-60 Hz |

| Operation Pressure | 350 bar |

| Working Pressure | 280 bar |

| Tested Pressure | 380 bar |

| Coach Stroke | 900mm |

| Maximum Load | 0 - 150 tons |

| Extension Speed | 0 – 590 mm/min |

| Retract Speed | 0 – 780 mm/min |

| Compliant Rubber Lubricant | Soft Soap or Other Suitable Lubricant (Optional) |

| Mold (Upper) Type of Ram | Replaceable Mold acc. to Suitable Wheel Type |

| Mold Type of Plate | Replaceable Mold acc. to Suitable Wheel Type |

| Main Carcass Manufacturing Method | Welded Manufacturing and Detachable Connections |

| Machine Fixing Method | Bolted Connection to Floor |

| Compression Plate | Precisely Machined High Strength Steel |

| Wheel Tyre Centering Method | Wheel Tyre Centering Apparatus |

| Replaceable Assembly Plates | Precisely Machined High Strength Steel |

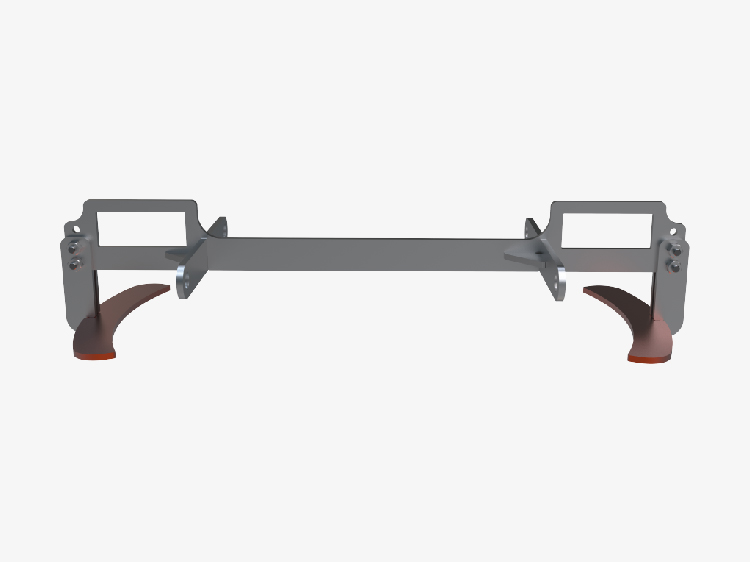

| Wheel Tyre Holder Arm | Reinforced Steel with Self Locking System |

| Compression Cone | Precisely Machined High Strength and Hardened Steel |

| Compression Cone Connection Method | Bolted Connection to the Wheel Center |

| Total Weight of The Machine | ~6200 kg (Excluding floor connection equipment) |

| Hydraulic Unit Connections | Safe Connection with Steel and Rubber Pipes |

| Hydraulic Unit Placement | On Floor Type |

| Safety | Mechanical Safety Precautions Against Hydraulic System Problems |

| Load Standby | Available |

| Load Hold | Available |

| Energy Source | 380V AC 3-Phase |

| Machine Control Method | PLC Controlled System |

| Motion Control Method | Operating Arm and Buttons |

| System Monitoring Method | HMI Screen |