Sand Filling Systems

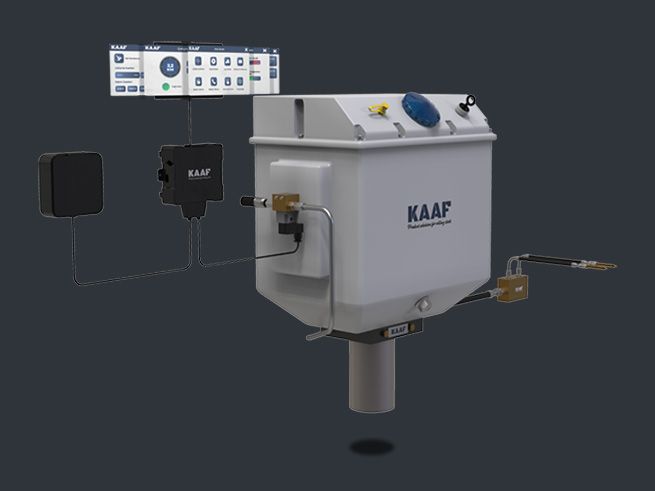

What is the Mobile Sand Filling System?

Railway vehicles consume sand to eliminate weak friction between the wheel and rail while operating. This lost sand must be refilled daily or weekly. Manually loading sand causes high labor hours and costs for railway vehicle operators. This workload directs operating companies to Sand Filling Systems (KDA) to refill lost sand conveniently, safely, and efficiently.

See the following pages to identify the KDA model needed.

Customer Requirements Determination:

To select the correct model of Sand Filling System (KDA) for your operation, please provide detailed information regarding the following conditions:

By providing this information, we can ensure the selection of the most suitable Sand Filling System for your needs.

Sand Specifications;

KDA performance largely depends on the sand properties. According to the German DBS 918224 standard, the sand content should be as in the table. Each model is tested with sand following these standards. If the sand differs from this standard, properties should be clearly defined, or 5 kg sand samples should be sent for performance testing.

| Sand Particle Size (mm) | Percentage of Particle (%) |

|---|---|

| > 2,5 | 0 |

| 2,0 – 2,5 | Max. 4,0 |

| 1,6 – 2,0 | Max. 15,0 |

| 0,7 – 1,6 | Min. 70,0 |

| 0,5 – 0,7 | Max. 15,0 |

| 0,1 – 0,5 | Max. 4,0 |

| < 0,1 | Max. 0,3 |

KDA General Features:

Power and Battery:

Operation and Control:

Performance and Efficiency:

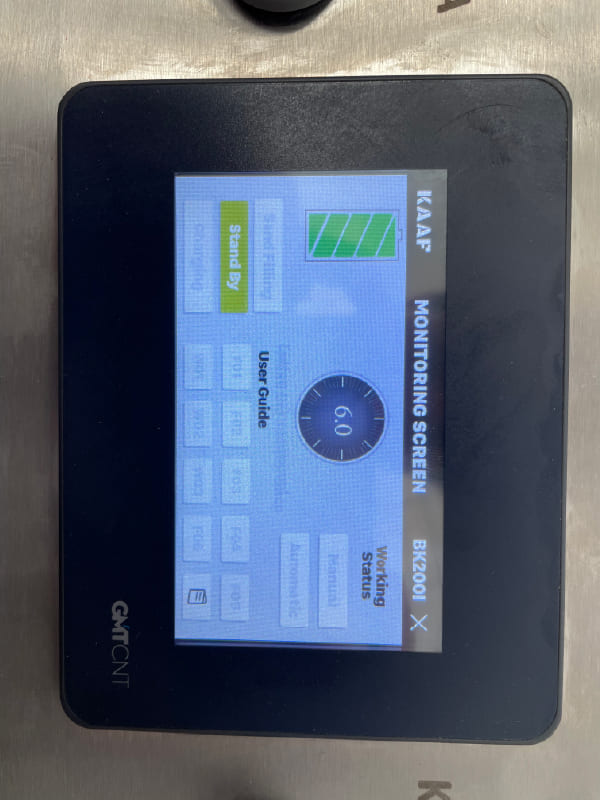

Sophisticated Monitoring and Diagnosis Software

Compact Controlling System

Filling Gun with an Integrated Start/Stop Feature and a Fully Mechanical, Failure-Free Dust Extraction System...

With a Watertight, Stainless-Steel Sand-Filling Cap and Water-Resistant Components, the KDA Can Operate Even in the Rain...

Overview of KDAs

Ultra - Back View

BH - Back View

EK - Back View

You are currently viewing from your mobile device. For this reason, you can access the product catalogue and the PDF table comparing the product models from the links below.

| KDA Features | Parameter and Explanation | BH200I | EK200I | BK200I | EK200I COMBI | BK200I COMBI | EK200I ULTRA | BK200I ULTRA | EK200I ULTRA + KOMBI | BK200I ULTRA + KOMBI |

|---|---|---|---|---|---|---|---|---|---|---|

| Sand Flow Rate With Internal Pressure Generator (1 Compressor) | kg/min | — | 15 | 15 | 15 | 15 | — | — | — | — |

| Sand Flow Rate With Internal Pressure Generator (2 Compressors) | kg/min | 30 | — | — | — | 30 | 30 | — | 30 | 30 |

| Sand Flow Rate with External Pressure Generator | kg/min | 30 | — | — | 30 | 30 | — | — | 30 | 30 |

| Automatic External Pressure Generator Connection and Dis-Connection Detection System | Special Pressure Switch and SW | ✓ | — | — | ✓ | ✓ | — | — | ✓ | ✓ |

| Dust Suction System | Failure-Free Mechanical System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Dimensions (LxWxH) | mm | 1380x980x1410 | — | — | — | — | — | — | — | — |

| Tare Weight | kg | 300 | 300 | 325 | 300 | 325 | 310 | 350 | 310 | 350 |

| Full Load Weight (Higher capacities are available) | kg | 600 | 600 | 625 | 600 | 625 | 610 | 650 | 610 | 650 |

| Sand Carrying Capacity (Higher capacities are available) | 200L - 300kg | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Operating Voltage | 24V DC | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Battery Type | LiFePO4 | — | — | — | ✓ | ✓ | — | ✓ | — | ✓ |

| Battery Capacity | Ah | 50 | — | 210 | — | 210 | — | 210 | — | 210 |

| Max Power Consumption | Ah | 4.5 | 52.5 | 52.5 | 52.5 | 52.5 | 96 | 96 | 96 | 96 |

| Integrated Inverter 220 VAC to 24VDC | Ah | — | 125 | — | 125 | — | 135 | — | 135 | — |

| External Power Supply Voltage | V AC | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 | 220 |

| Noise Emission Level | dBA | < 59 | < 79 | < 79 | < 79 | < 79 | < 79 | < 79 | < 79 | < 79 |

| Integrated Battery Charger | Ah | 7* | — | 30* | — | 30* | — | 30* | — | 30* |

| Cable Drum | Meter (m) | — | 10** | Optional | 10** | Optional | 10** | Optional | 10** | Optional |

| Hose Drum | Meter (m) | 10** | — | — | Optional | Optional | — | — | Optional | Optional |

| Start / Stop Command Over The Filling Gun | On the Gun | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Sand Tank Automatic Filling Detection | Smart Sensor | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Customer Support via Internet | Remote WIFI Connection | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Smart Diagnosis and Monitoring System | With Touch Screen | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Sand-Filling Hose Blockage, Clearing System | Special Pneumatic System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Sand-Filling Performance Measurement System | Sophisticated Software | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Maintenance Tracking System | on Board | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Forklift Truck Lifting Interface | Mechanical Interface | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Operation Under Rain | Special Sealing Systems | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| UV Resistance Outdoor Run | Special Paint, Housing, Screen etc. | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

|

* Values of the integrated battery charger can be increased according to customer demand. ** Drum lengths can be increased according to customer demand. |

||||||||||