SUBSYSTEMS

Rolling stock subsystems are designed to provide optimal performance, reliability, and safety in railway operations. The portfolio includes friction management systems, bogie technologies, and drive control systems, each engineered to meet industry standards and integrate seamlessly into various rail vehicle types. These subsystems are developed to enhance functionality, durability, and long-term operational efficiency, ensuring smooth and dependable railway performance in diverse operating conditions.

Friction Management Systems

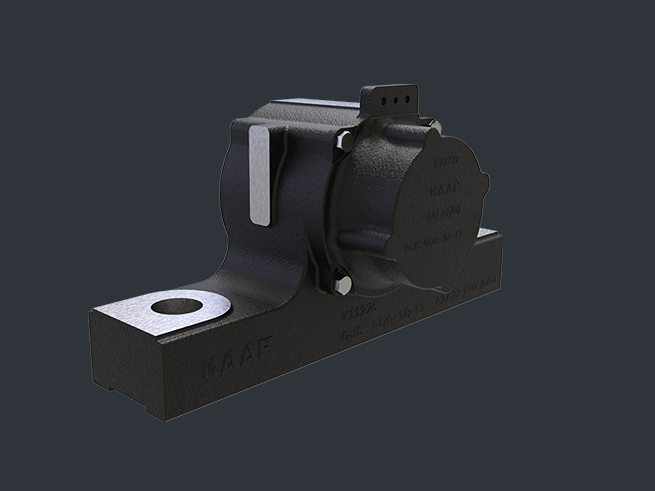

Advanced friction management systems effectively address the critical challenges of wheel-rail interaction, resulting in significant improvements in drive comfort and safety. Kaaf offers two essential products to manage friction: the Flange Lubrication System and the Sanding System. The Flange Lubrication System minimizes friction on flanges and reduces wear on wheel and rail, extending wheel and rail life while improving efficiency. The sanding system improves the friction coefficient between the wheel and the rail. It reduces the impact of slippery railhead conditions by pouring sand between the wheel and the rail. Both systems have variations for all sorts of railway vehicles.

The sanding system is used to increase the frictional force by blasting sand between the rail and the wheel in rolling stock.

In railway vehicles, undesirable friction (negative friction) between the rail and the wheel body is the main contributor to...

Bogie Technologies

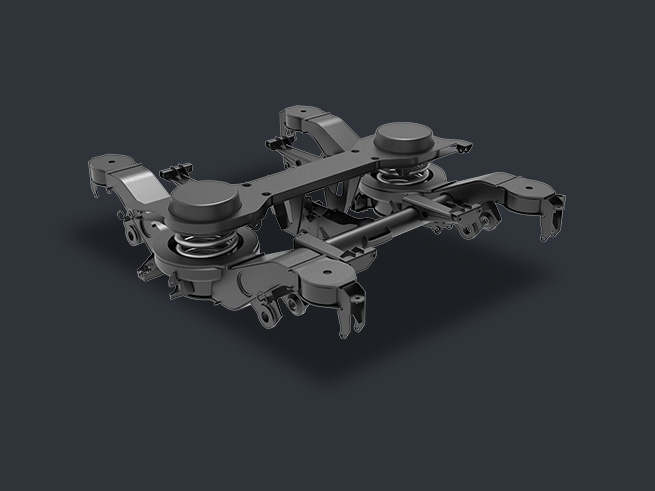

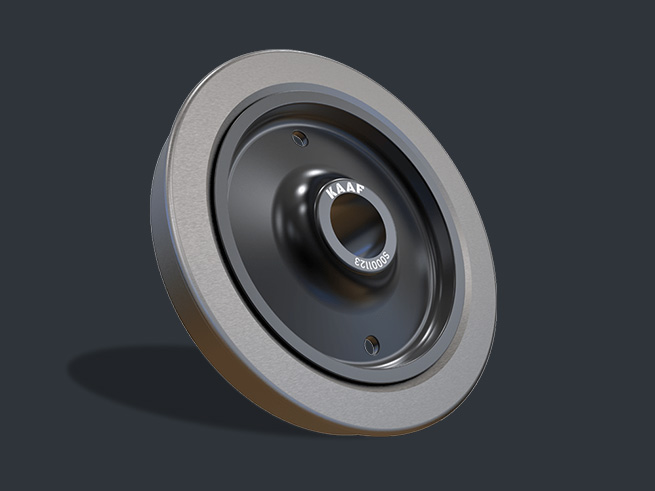

Bogie technologies encompass a comprehensive range of products engineered for stability, durability, and safety. Kaaf offers three core components: bogies, axleboxes, and resilient wheels. The bogie provides the structural foundation, ensuring strength and balance under varying loads and velocities. The axlebox is designed for precise alignment and shock absorption, enhancing reliability against dynamic forces. Resilient wheel reduces vibration and noise, making a more comfortable and efficient ride. Together, these components form a robust solution that meets the challenging demands of modern railway systems.

Resilient wheels are used effectively to enhance navigational comfort and reduce maintenance costs for rolling stocks.

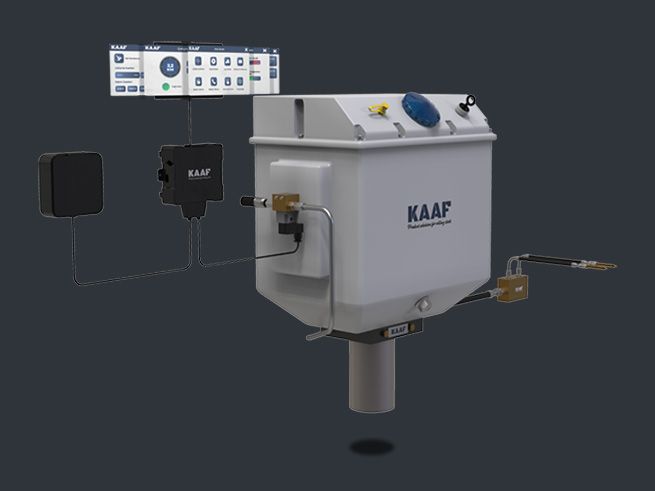

Driving Control Systems

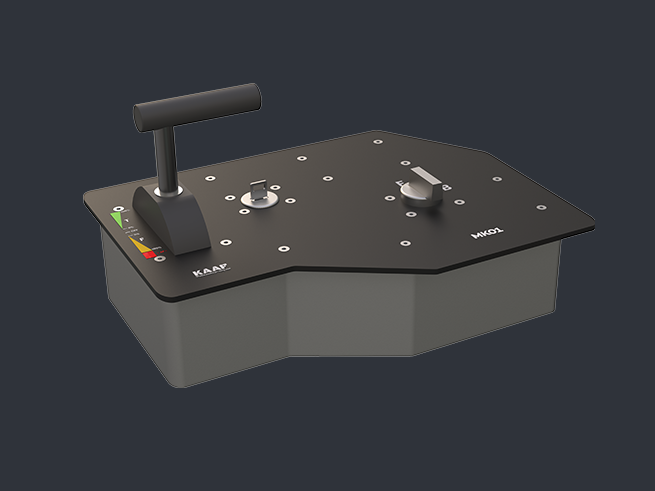

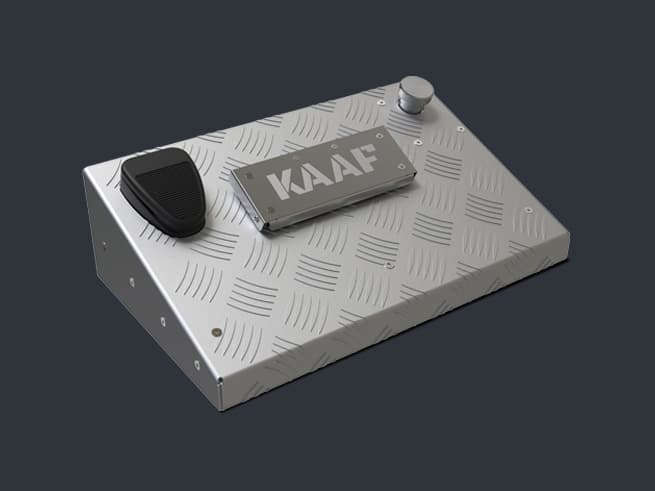

Driving control systems are designed to enhance safety for cruising and ergonomics for operators. Kaaf offers three core components for driving control: Master Controller, Driver Footrest, and Foot Pedal. The master controller allows precise control of the train's movement, acceleration, and braking. The driver moves or stops the vehicle with this device. The Driver Footrest is designed for operator comfort during cruise, promoting better posture and reduced fatigue. The Foot Pedal provides responsive and precise control that can be customized according to the function requested, such as deadman, external horn, braking, etc.

The master controller allows precise control of the train's movement, acceleration, and braking. With this device, the driver...

It enhances the driving comfort of the drivers and takes the vehicle and passenger safety to the next level.

The Foot Pedal is a rugged switching device for footing applications. The modular design enables the switching device to be...