Flange Lubrication System

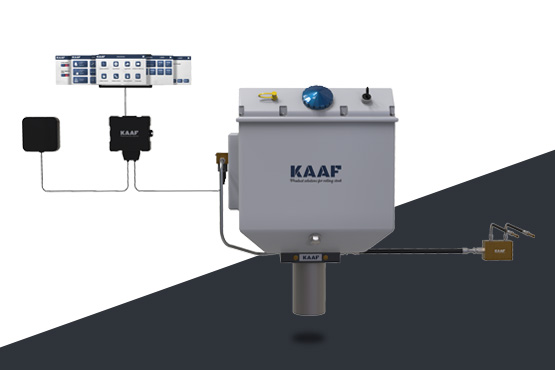

In railway vehicles, undesirable friction (negative friction) between the rail and the wheel body is the main contributor to high maintenance costs, noise and environmental pollution, fuel consumption, and potential derailments. By carefully controlling the timing and rate of oil spraying, The Flange Lubrication System reduces the damaging effects of friction, increase passenger comfort, while reducing maintenance, fuel expenses, and business risk. Through its user-friendly interface, the Flange Lubrication System promptly notifies the driver of the lubrication process and allows the operator the opportunity to control some processes within predetermined limits. The KAAF Flange Lubrication System, which is adaptable to diverse usage and environmental circumstances, keeps working under any circumstance.

Technical Specifications

- Oil Tank and Pump

- Pump Type:Pneumatic Actuated

- Stroke Volume:0.1 / 0.2 / 0.3 / 0.4 cc per stroke

- Compressed Air Requirement:4-10 bar (Optimal: 5-6 bar)

- Oil Tank Capacity:6-20 liters (Optional)

- Material:Aluminum

- Operating Temperature:-40°C to +70°C

- Lubricant:NLGI 00/000 (Customized per customer requirements)

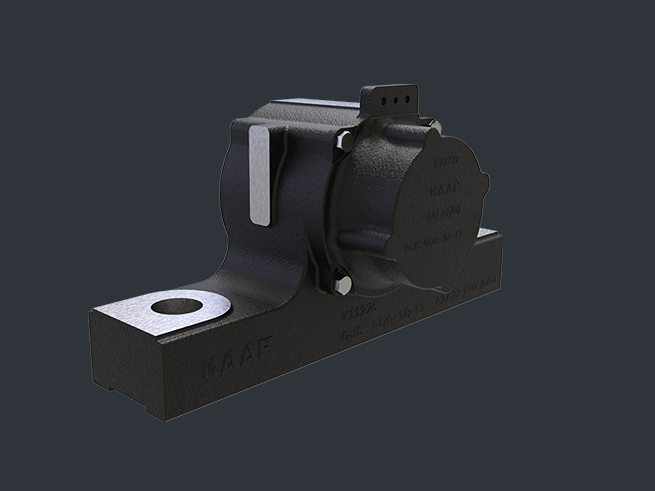

- Spray Nozzle

- Material:Stainless Steel or Brass (Optional)

- Air Consumption:1 to 2 liters/sec

- Operating Temperature:-40°C to +70°C

- Distributor

- Outputs:2 or 4 (Optional)

- Material:Stainless Steel or Brass (Optional)