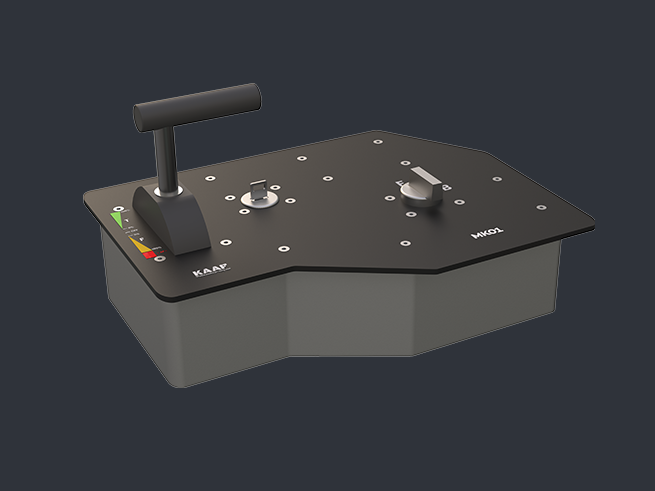

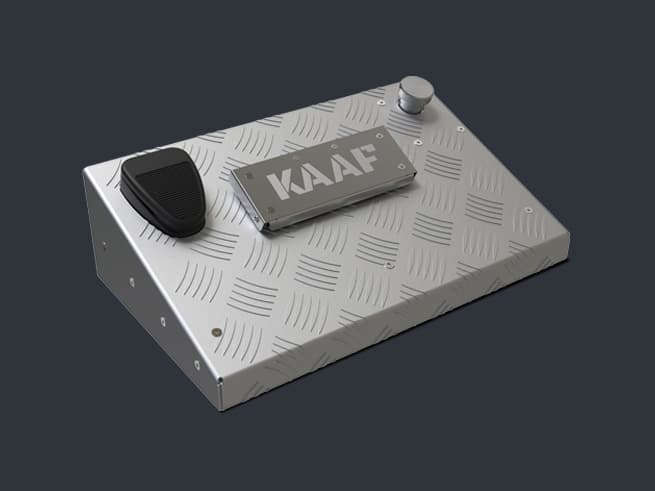

Master Controller

The master controller allows precise control of the train's movement, acceleration, and braking. With this device, the driver can move or stop the rolling stock efficiently. It also optimizes the train's energy consumption and performance along its route. As one of the most critical pieces of equipment, the master controller ensures the safe operation of the train.

| Master Controller Specifications | |

|---|---|

| Specification | Description |

| Control Functions | Management of traction speed, braking force, and travel direction |

| Handle Motion | Notching (stepped) or step-less motion. Both options are possible in combination |

| Position Transmission | Potential free contacts or analog-digital converter |

| Angle Converter Range | 300 degrees |

| Low Voltage Interface | Connector, modular DDD type |

| Front Plate | Customized design based on selected functions |

| Control Voltage | Specified per customer requirement; 24V DC (+25% to -30% tolerance) |

| Electrical Specifications | 24V DC control voltage, dielectric test voltage: 1500V (between live parts and ground), 2000V (across open auxiliary contacts) |

| Operating Temperature | -40°C to +70°C |

| Durability and Reliability | Design life exceeding 10 million switching cycles; MTBF over 50,000 hours |

| Safety Features | Mechanical interlocks to prevent incorrect operation; options for dead man's switches and automatic lever reset mechanisms |

| Modularity and Customization | Modular design allows easy integration into different driver desks and customizable switching and latching elements |

| Application Range | Suitable for high-speed trains, locomotives, EMUs, trams, and light rail vehicles; compatible with both AC and DC systems |

| Compliance Standards | IEC 61373, EN 501455, EN 50121-3, EN 60077 and UIC 612 |